Introduction

The industrial development of India has actually been sustained by the advancements in oil devices. These equipments have reinvented the production field, enabling boosted efficiency, efficiency, and accuracy. In this write-up, we will certainly check out exactly how oil machines have actually played an essential role in India's commercial development and examine the numerous types and applications of these machines. From India Hand Equipments to India CNC Machines, each type has contributed to the country's increase as a commercial powerhouse.

Oil Devices: The Foundation of India's Manufacturing Sector

India Hand Device: A Game-Changer in Small-Scale Industries

India Hand Equipments have actually played a vital duty in the development of small-scale industries in India. These functional machines are made use of for numerous jobs such as cutting, boring, shaping, and grinding. With their compact size and very easy procedure, they have actually come to be important tools for craftsmens and artisans throughout the nation. The cost and resilience of India Hand Equipments have made them available to small companies and entrepreneurs, empowering them to contend in the international market.

India Machine Components: Precision at its Best

Precision is vital when it pertains to making maker components, and India Machine Components have established brand-new requirements in this regard. These makers use innovative modern technologies such as computer system mathematical control (CNC) to produce complex components with utmost accuracy. From equipments to shafts to valves, these parts are the building blocks of various markets consisting of auto, aerospace, and protection. The high-quality output of India Machine Components has not just met residential need however additionally positioned India as an international hub for precision engineering.

India CNC Machines: Releasing Automation

Automation has actually been a game-changer in modern-day production, and India CNC Machines have played a critical role in this makeover. These computer-controlled machines can perform complex tasks with minimal human treatment, resulting in boosted efficiency and lowered costs. From crushing to transforming to piercing procedures, CNC makers have changed the manufacturing process by ensuring consistency, accuracy, and rate. The convenience and effectiveness of India CNC Machines have made them essential throughout a large range of industries, including vehicle, aerospace, and electronics.

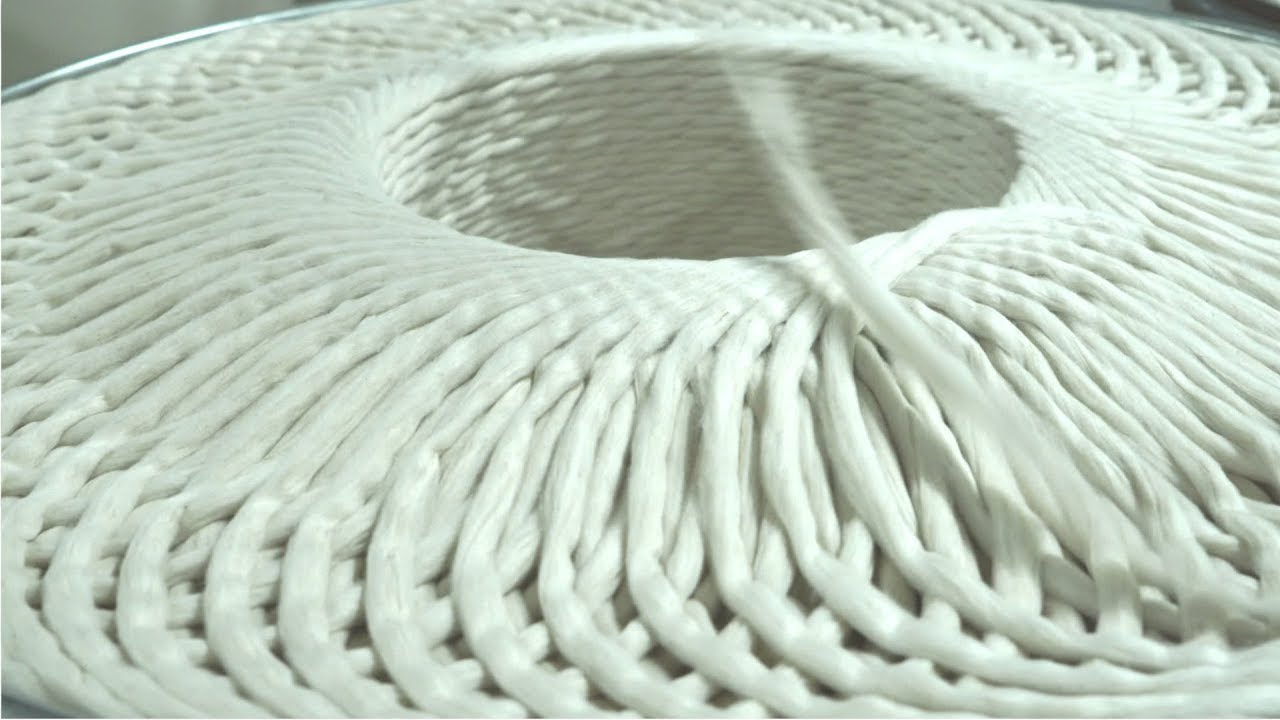

India Mill Maker: Powering the Textile Industry

The fabric industry is among the largest contributors to India's economic climate, http://kameronvhkf013.theburnward.com/the-development-of-india-s-cnc-machines-a-look-into-the-future-of-engineering-modern-technology and India Mill Machines have actually contributed in its development. These makers are made use of for numerous processes such as rotating, weaving, and dyeing, making it possible for the production of high-quality textiles in big amounts. With their advanced functions and automation abilities, India Mill Machines have actually improved effectiveness and lowered labor prices in the textile sector. This has not only boosted residential production yet likewise positioned India as a major gamer in the international fabric market.

India Digital Equipment: Driving Innovation

The electronic devices industry is swiftly evolving, and India Electronic Equipments have played a critical function in driving development. From published circuit board (PCB) setting up to chip mounting to soldering operations, these devices make certain precision and dependability in electronic manufacturing. The advanced functions of India Electronic Machines allow high-speed manufacturing with minimal errors, meeting the ever-increasing demand for electronic items. The growth of this industry has not only developed job chances yet also contributed significantly to India's GDP.

FAQs

Q1: What is the role of oil makers in India's commercial growth? A1: Oil makers have actually been instrumental in driving productivity, efficiency, and precision in numerous sectors. They have allowed small-scale markets to compete worldwide and placed India as a center for precision engineering.

Q2: Just how have India Hand Machines empowered small companies? A2: India Hand Machines are affordable, resilient, and easy to operate. They have allowed craftsmens and artisans to improve their productivity and quality of result, therefore encouraging them to complete in the international market.

Q3: What makes India Machine Components attract attention? A3: India Machine Components utilize sophisticated technologies such as CNC to make sure accuracy in production. Their top quality result has not just met domestic need yet additionally placed India as an international center for precision engineering.

Q4: Just how have India CNC Machines reinvented the manufacturing procedure? A4: India CNC Machines have released automation in manufacturing, leading to increased productivity and lowered costs. Their convenience and efficiency have made them crucial across numerous industries.

Q5: What is the relevance of India Mill Machines in the fabric sector? A5: India Mill Machines have enhanced performance and minimized labor expenses in the fabric market. They have made it possible for massive manufacturing of premium textiles, placing India as a significant gamer in the worldwide fabric market.

Q6: How have India Electronic Machines added to technology? A6: India Electronic Machines guarantee accuracy and reliability in digital production. Their advanced features allow high-speed production, satisfying the boosting demand for electronic products and driving innovation.

Conclusion

Oil equipments have actually been the driving force behind India's industrial growth. From hand devices to CNC devices, each type has actually contributed to raised performance, efficiency, and accuracy in various markets. These makers have actually empowered small businesses, positioned India as a global hub for accuracy engineering, reinvented the production procedure, powered the textile market, and driven technology in electronic devices. As India remains to welcome technological advancements, oil devices will certainly play an even more significant duty in shaping its industrial landscape and fueling further growth.